Fully automatic welding of small batch sizes

Robot welding cell with built-in flexibility

MAHA, a world leader in workshop equipment supplies, has put into operation a robot welding system that sets new standards in terms of flexibility at its corporate headquarters in Haldenwang. Programs for over 150 welded assemblies have been set up after a year of intense activity – with a continuing upward trend.

MAHA is one of the global market leaders in workshop and vehicle testing equipment. The company, founded by Winfried Rauch in Allgäu in 1969, has quickly grown to become a global player with a worldwide workforce of over 1,200 as well as 150 agencies and 17 international subsidiaries.

At the Haldenwang site, about 750 employees produce the full range of workshop equipment, from test stands and vehicle lifting platforms to various types of testing equipment for cars, commercial vehicles, motorbikes and special-purpose vehicles. Workshops and test organizations all over the world value the superior quality of the products that have an excellent reputation for durability and reliability.

Small batch sizes from 10 to 100

Erich Schmölz, head of the robot welding department at MAHA, sums up what this commitment to quality means for production: “On the robot system we must produce welding assemblies in small batch sizes and in absolutely reproducible quality. In the case of our truck lifting platforms, for example, that are offered with a maximum payload of up to 60 tonnes, human lives depend on the correct execution of welding seams. The requirements placed on welding results in quality testing are, depending on relevance, correspondingly stringent.”

Premium quality accompanied by maximum flexibility – MAHA has achieved this “squaring of the circle” with a pathbreaking robot welding system conceived and implemented by the Yaskawa welding experts in close cooperation with the specialists at MAHA in a turn-key system now operating in Haldenwang.

Robot welding system designed and built in a turnkey package

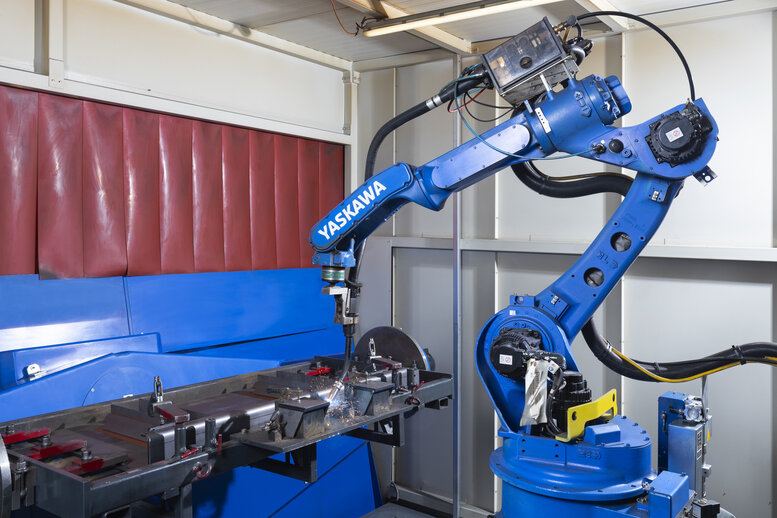

“The complete cell is primarily composed of standard Yaskawa components, whereby the actual guarantors of flexibility are the six-axis MOTOMAN MA2010 high-speed welding robot with DX200 controller and five-axis R2C servo positioner with two stations for parallel welding and loading while processing,” stresses Roland Hermann, Yaskawa Sales Manager.

What first strikes the eye when looking at the cell is the approx. 15-degree inclination of the positioner, allowing the operator to place and clamp the parts simply and ergonomically on the loading side. The changing of jigs – the name given to the mounts for the respective component variants – is also facilitated by this design trick, reducing retooling times to between five and ten minutes.

If the positioner is rotated by 180 degrees in the working area, the inclination creates a raised working position for the welding robot, which for this reason is mounted on a plinth. A further advantage of this position is the excellent accessibility to the robot. In combination, the five NC axes of the R2C positioner and the six robot axes, optimally synchronised by the DX200 controller, permit a perfectly flat welding position in every case.

Offline programming boosts productivity

What welding specialist Schmölz particularly appreciates about the system is the offline programming option: “Via CAD data we can program any welding assembly offline parallel to operation, precisely calculate welding times, specify joining sequences to ensure minimum delays, avoid collisions and much more. In our operating conditions with multiple small parts, offline programming significantly boosts productivity.”

Often two different assemblies are alternately welded in the system – no problem with the 2-station positioner. However, care must be taken to ensure that insertion times are shorter than welding times, as downtimes are to be avoided at MAHA. That is why the company opted for the MOTOMAN MA2010. The six-axis robot has a reputation for being resilient and can perform its given tasks in multi-shift operation around the clock, always with the required path accuracy. The machine delivers process-reliable welding results, part by part, without deviating from the given tolerances. The slim robot has a dynamic approach to its work and ensures maximum output. With a payload of 10 kg, it has an impressive range of 2010 mm.

Reliability and know-how facilitate the decision

It goes without saying that prior to investing in this system, the decision-makers at MAHA also considered the products of other manufacturers. But in their deliberations they always returned to Yaskawa. One of the contributing factors was assuredly that MOTOMAN welding robots had been operating for the past 22 years at the Haldenwang plant with a high degree of reliability.

But besides this impressive commitment to quality there were many other factors in favour of Yaskawa. Erich Schmölz puts the main criteria in a nutshell: “Yaskawa has an incredible amount of experience and can design turnkey welding systems exactly to customer requirement using many of its own standard components. We benefit from this know-how, as well as the exemplary service and proverbial reliability.” The seamless integration of the welding system into production and trouble-free operation ever since can be deemed normal.

Top performance prompts further investment

The system operators are also enthusiastic about its performance. They especially appreciate the excellent accessibility of the generously dimensioned insertion area that is secured by floor scanner, photoelectric sensors and safety guards. Here there is enough space to deposit parts with the lift truck or fork-lift. Simple and convenient operation of the system likewise facilitates the daily work. This also includes a further glare shield on the positioner, creating a completely enclosed welding area. A powerful welding smoke extractor ensures that the workshop air is not polluted.

All in all, the high MAHA expectations placed on the system have been entirely fulfilled in practice. “This system has enabled us to realise our primary objective of increasing the flexibility of welding processes with small batch sizes. Despite the huge range of parts, the productivity of the system is at peak level, and our plans for a second, identical installation are already well advanced,” Schmölz sums up.